Redefining Real-Time Conveyor Monitoring

The Lorbrand Sensor Seal™ can optimise operations, enhance safety, and reduce costs through advanced predictive maintenance at an affordable price

What is the Sensor Seal™?

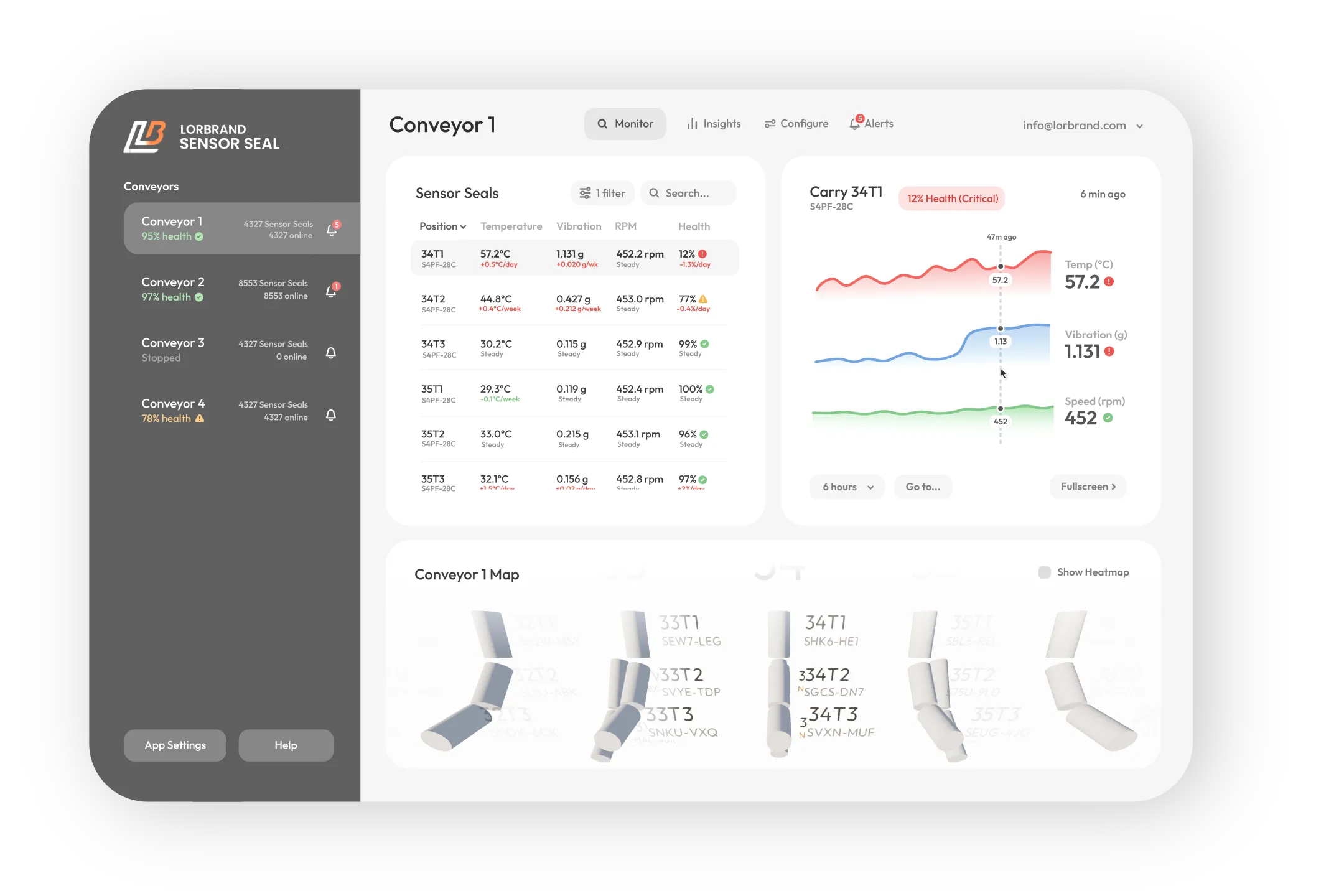

Designed and manufactured by Lorbrand, the Sensor Seal is a low-cost wireless device installed on the end of our idlers, gathering parameters critical to determining their health: temperature, vibration, and RPM.

Using machine learning, health scores are determined for all Sensor Seal-equipped idlers, allowing for the early detection of failures, enabling preventative maintenance and minimising costly downtime.

Monitor and Optimize with Ease

Seamlessly access real-time conveyor health and performance metrics. Our intuitive dashboard delivers real-time insights into each Sensor Seal, empowering you to detect issues early and streamline maintenance efficiently.